Turbojet engine

Fully functional propane fueled jet engine + test stand, with integrated oil cooling, and ignition system

Design

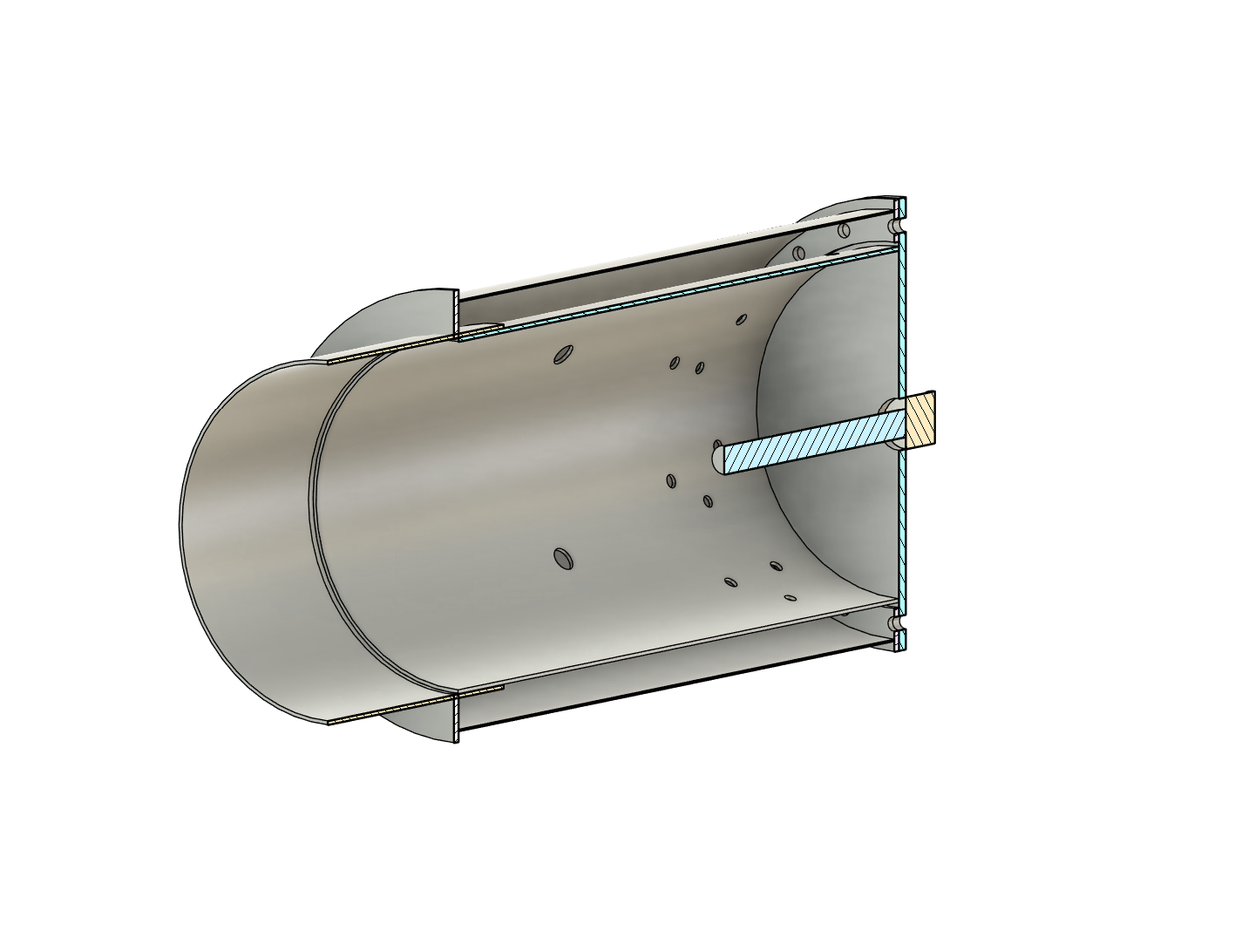

Combustion Chamber: Starting with turbocharger measurements, I calculated the combustor sizing and internal gas flow holes with assistance from JetSpecs. With the general dimensions, I then designed a refined model of the combustion chamber through Fusion 360.

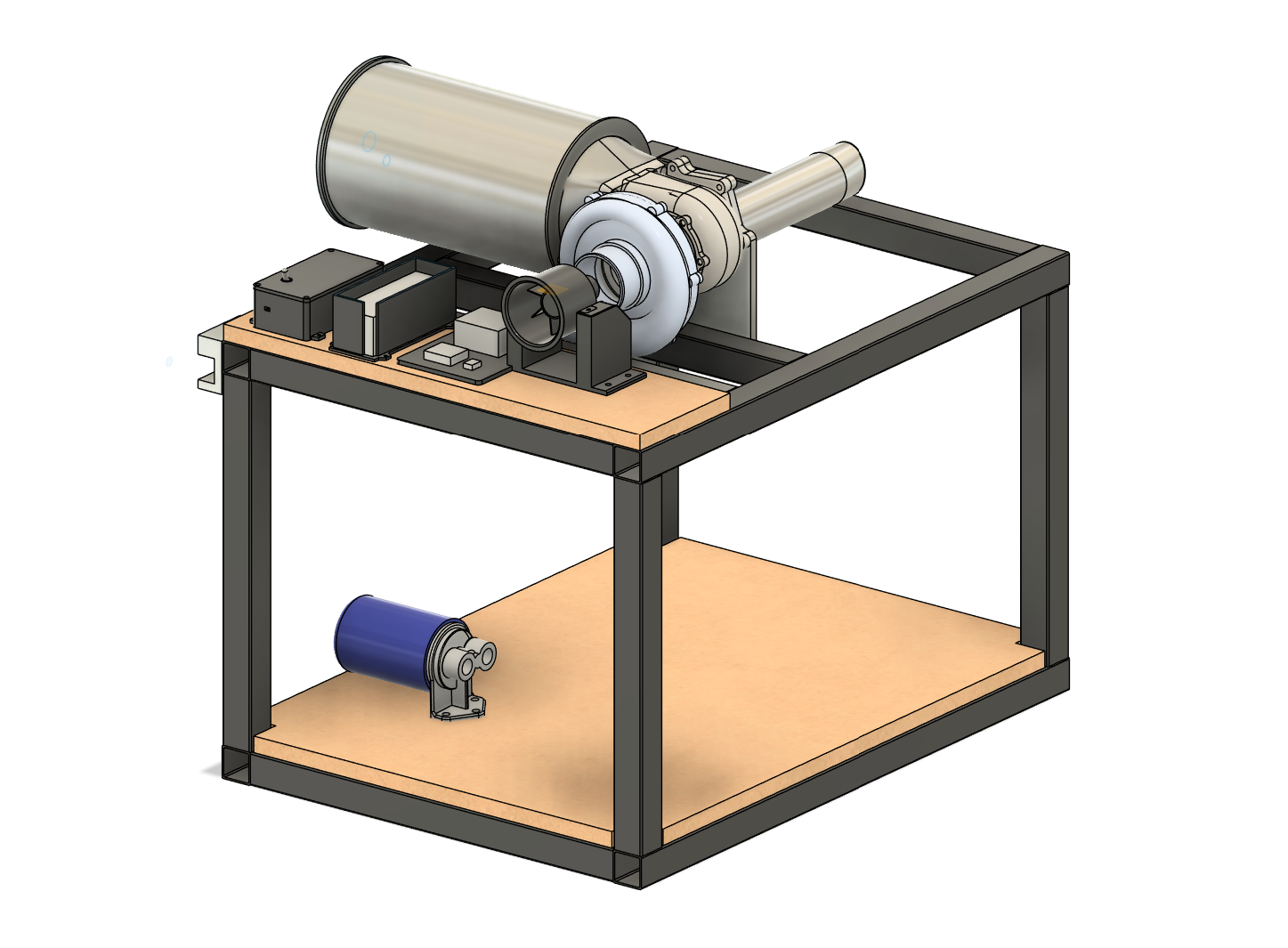

Test Stand: The bench was dimensioned to house all components including the main engine, oil pump, cooling system, and filtration system, while providing a solid and stable base during testing.

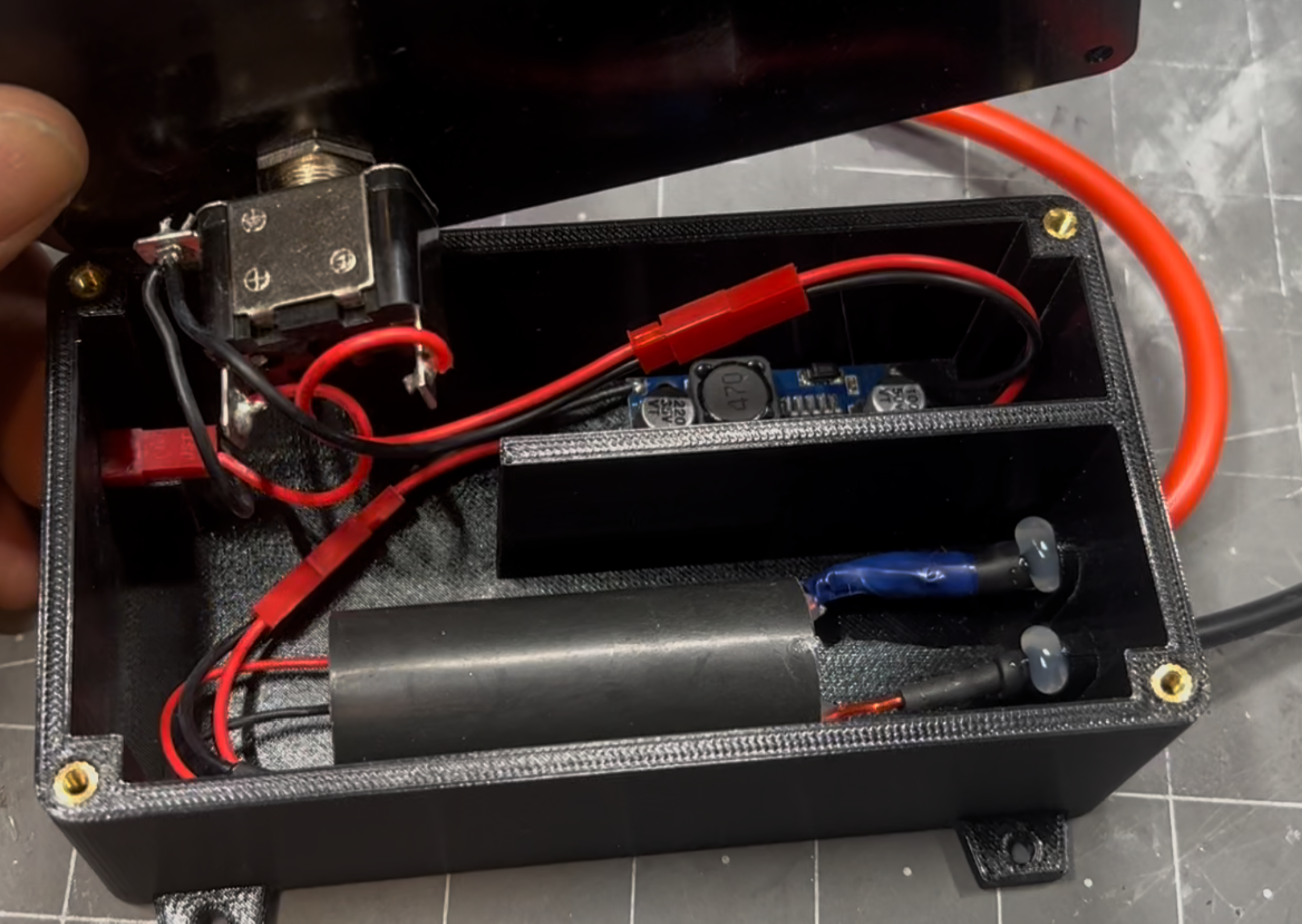

Ignition System: The ignition circuit uses a buck converter to step down voltage from the main battery, powering a high-voltage generator connected to a spark plug housed inside the combustor.

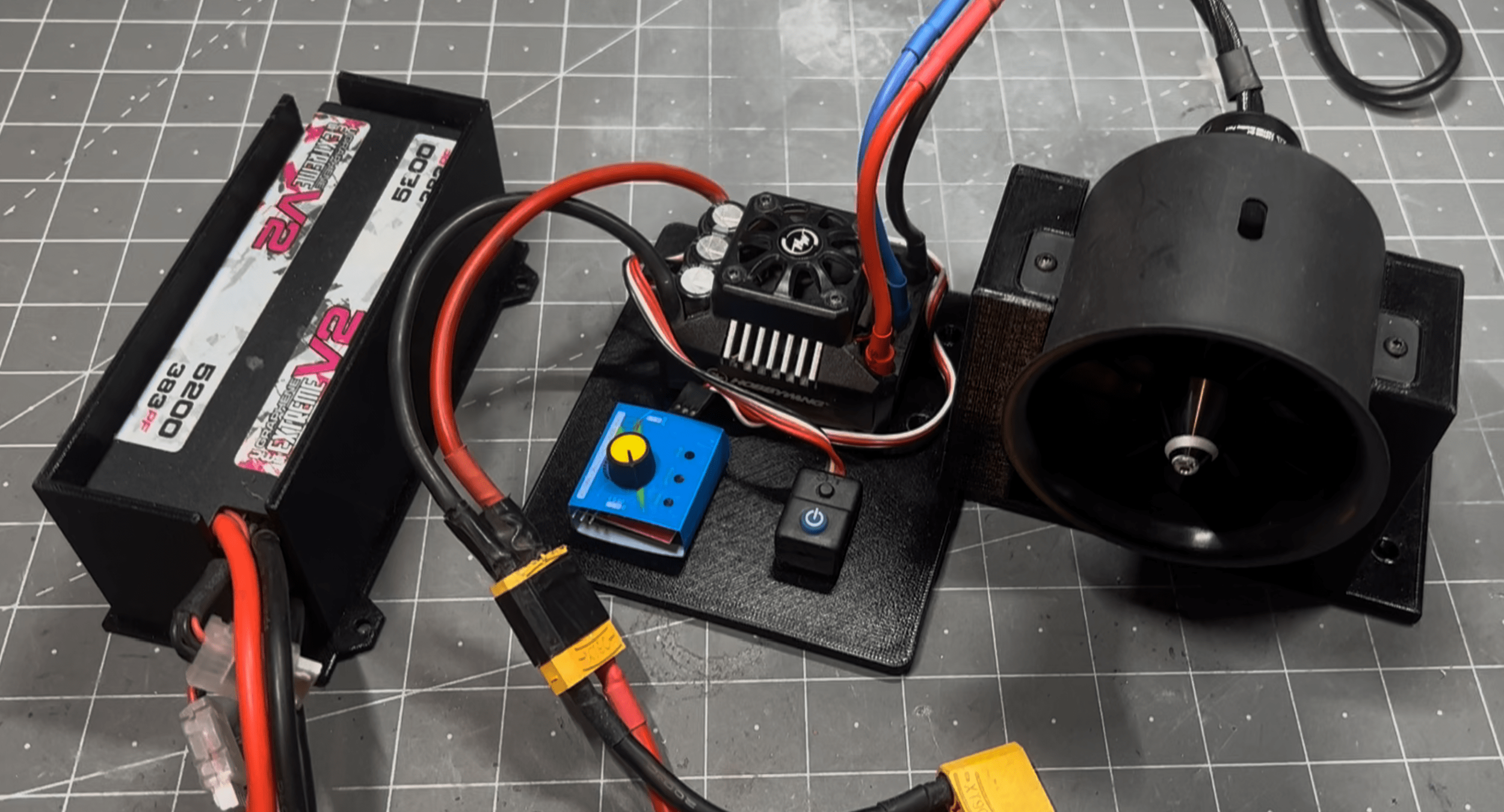

Starting System: Initial spooling is achieved using a 22V 6S electric ducted fan, providing airflow until the turbine reaches self-sustaining combustion.

Build

Metalworking: The combustion chamber is fabricated from a stainless-steel fire extinguisher body combined with rolled stainless sheet.

Machining: Mounting flanges (steel and stainless) were machined, requiring fine tuning of toolpaths and feeds to compensate for an underpowered CNC mill not ideally suited for cutting steels.

Welding: The combustion chamber was TIG welded for precision due to the thin material, while the support frame was MIG welded for simplicity and speed.

Test

This project gave me a chance to pull together a lot of different skills, machining, welding, wiring, and system design, into one working engine.

Figuring out how to make all the subsystems function gave me a lot of insight about integration and troubleshooting, and I’d like to keep iterating though a thrust measurement jig and afterburner.