Fully Integrated CNC enclosure + Workbench

Overview

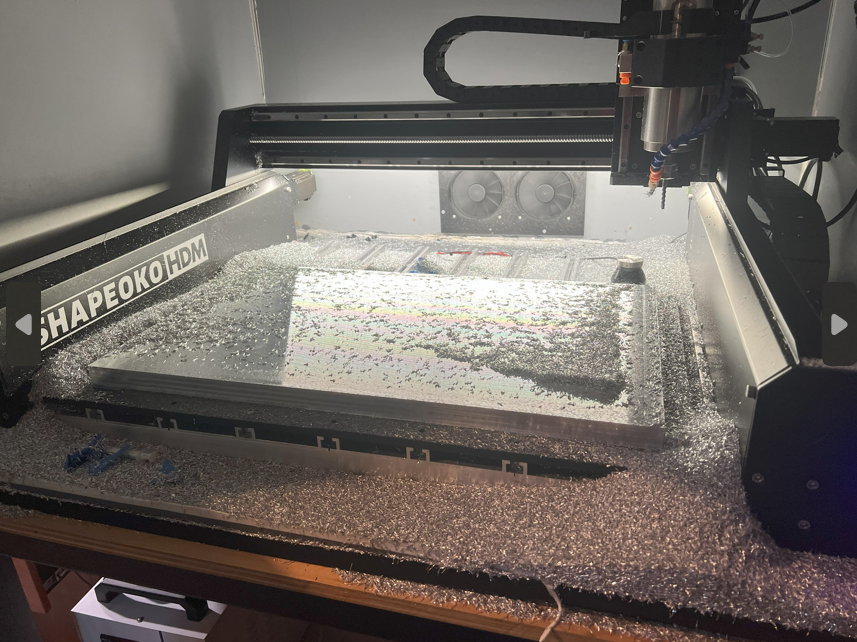

While building the jet engine, I realized my CNC setup needed a major overhaul. During machining chips were spilling everywhere and the smell of coolant filled the garage.

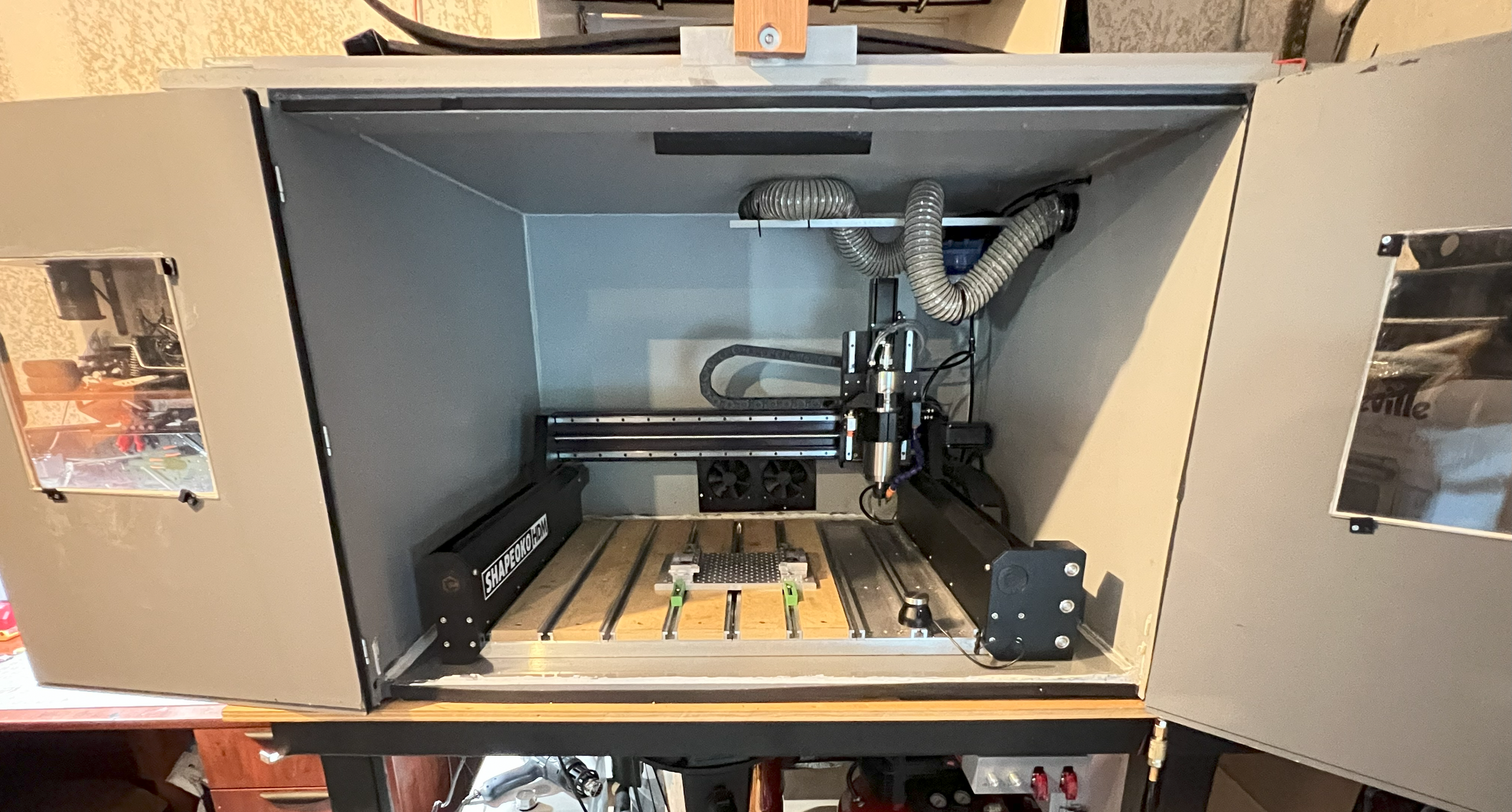

To address this, I set out to build a relatively simple and cost effective workbench and enclosure that housed and integrated everything needed to make machining easier and more efficient.

Starting with a rough 3D scan of my workspace to simplify the sizing process in CAD, I created a parametric model for which I could easily tweak the dimensions of the workbench to fit everything I needed.

Features

Sound Isolation: Built out of 3/4 MDF with double panel acrylic viewports, the sealed enclosure offers a 15 decibel (3x) noise reduction from an unenclosed machine while actively machining.

Modular Fixturing: Custom aluminum M6x20 fixture plates greatly simplify workholding, reduce setup time, and improve repeatability.

Multimaterial Compatibility: Integrated mist coolant system with alcohol mix for aluminum and traditional coolant for ferrous machining; quick-connect shop vac port for efficient wood and plastic cutting.

Negative Pressure Air Circulation: To avoid buildup of hazardous coolant fumes, it utilizes an externally venting negative pressure air ventilation system that also prevents coolant mist and dust from leaving the enclosure.